RESIN

Explore All ChemicalsWhat RESIN we can supply

Resin products including impact resistance resin for meatl, water-based anti-corrosion for metal, anti-fog coating material cured by UV and self-healing/self-repair coating.

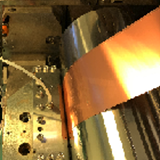

Impact Resistance Resin For Metal

Features: A new type of water-based adhesive that has good adhesion to copper and aluminum surface. It can improve porosity of copper and aluminum, and it has good coating flatness.

Applications: When metal processing, the insulation and adhesion of the resin can be maintained well.

Coating method: Slot Die Coating

Recommended processing conditions: 1. Coating amount: 70~75g/m2. 2. Drying conditions: 60°C/3 minutes→120°C/3~4 minutes (dry film thickness 20~22um).The required film thicknesses is different that the curing condition will be different, so you need to adjust the best processing conditions by yourself. 3. Mature conditions: A.60°C/24hr B.25°C/72hr.

Storage conditions: The storage period is 6 months, and the recommended storage environment is 5°C~35°C to avoid condensation. This product should be placed in a ventilated, shaded place, avoid high temperature or direct sunlight. It needs to be sealed and stored to avoid moisture volatilization and surface dried.

Packing:packed by zinc plated steel drum.Net weight of each drum is 200KGs.

Specification:

Apperance: milky white liquid

Solid Content (%): 34.5± 2

Viscosity (cps/25°C): below 600

100% Modulus(kg/cm2): 200±50

Tensile Strength(kg/cm2): 200↑

Elongation (%): 100↑

pH: 7-9

Water-Based Anti-Corrosion Resin For Metal

Features: Water-based environmentally friendly paint with acid and alkali resistance, corrosion and rust resistance, excellent heat resistance, weather resistance, impact resistance, hardness can reach more than 7H, and has good chemical resistance and high friction resistance.

Applications: Coated on metal surface, this coating can provide metal anti-corrosion performance.

Coating method: Dip coating, spraying.

Storage conditions: Store in a closed, dry, shaded place, away from heat and fire; it can be stored for at least 6 months at a temperature of 25°C.

Packing: 20kg/PE drum

Specification:

Appearance: Slightly transparent liquid

pH: 10~12

Density: 1.05~1.15

Solid Content: 16%

Viscosity: <100 CPS

Adhesion (Cross Cut): 100% no peeling

Solvent Resistance (Ethanol,Acetone,MEK,Toluene): ok

Salt Water Spray: 1000 hours

Wipeable Anti-Fog Coating Material Cured by UV Light

Features: This resin is a modified hydrophilic resin, which is an ideal and durable long-term anti-fog product. After use, this product can form a strong anti-fog film layer on the surface of the plastic substrate. When water vapor contacts the surface of the substrate, it can spread quickly and evenly without forming water mist, thus achieving an anti-fogging effect. Provide a long-lasting and durable super anti-fog solution.

Application: It can be used as anti-fog treatment of building door and window glass, refrigerator, motor vehicle windshield, spectacle lens, PET, PC, lens of photographic or laboratory equipment and agricultural plastic film.

Coating Methods: spraying, rolling, dipping, etc. depends on the operating conditions and operating materials.

Storage conditions: The product must be stored in a dry and cool environment to avoid qualitative changes caused by the absorption of moisture in the air.

Packing: 20kg/PE drum. This product needs to be packaged with UV-isolated material, and avoid contact with the light source to prevent the product from curing and agglomeration due to light reaction.

Specification:

Resin Composition: PU, Acrylic

Solid Content: 50%

Appearance: Clear liquid

Viscosity (25°C,#2 Iwata viscosity cup): 9~11 sec

Hardness (750g/100um PET): H

Dried Film Thickness: 6~8 um

Dipped in 100°C boiling water (30 min): Keeping Anti-fog, no peeling

High Temperature 60°C*96Hr: Keeping Anti-fog, no peeling

Low Temperature -10°C*72Hr: Keeping Anti-fog, no peeling

Transmittance: >90%

Self-Healing / Self-Repair Coating

Features: This is a self-healing coating with excellent self-healing ability, and anti-fouling. This coating has the function of automatically repairing small damage caused by external forces. This is a long-lasting self-repairing resin, suitable for spraying process and easy to operate.

Application: Automotive tint film, cellphone case, etc.

Applicable Material: PC, PET, TPU, TPE, etc.

Specification:

Contact Angle: &qt;100 degree

Copper Brush Scratch Resistance: < 40 seconds (standard: 500g load, recoverable time after copper brush rubbing 10 times)

Oil-Resistant Pen: no obvious color residue (standard: wipe after marker graffiti)

QUV:adhesion 0 ~ 1 level △E<2 (standard: 0.8W/cm2, 340nm, 1000 hours)

Back to CHEMICAL